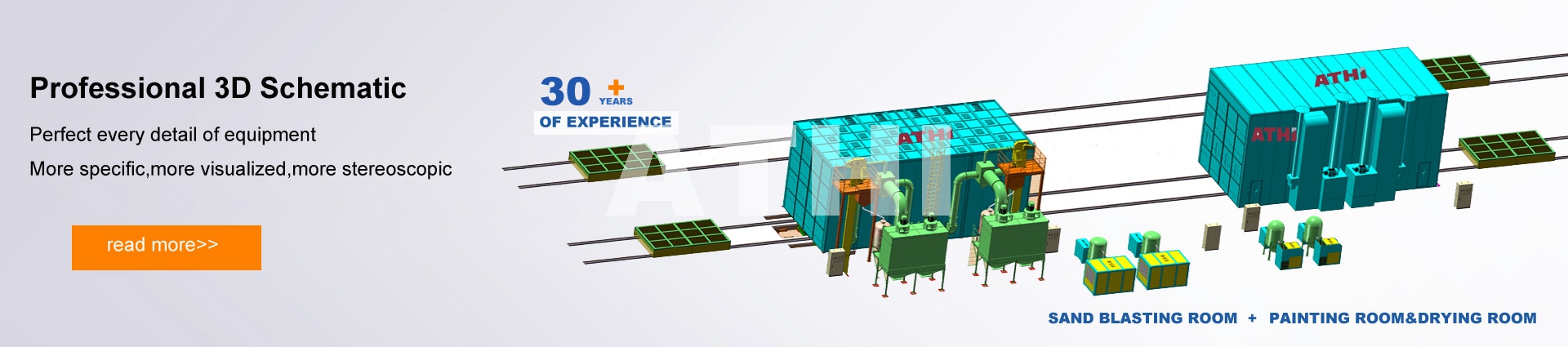

We can design and manufacture different size of steel plate pretreatment line according to customers' requirement. Please send your detail inquiry to our email.

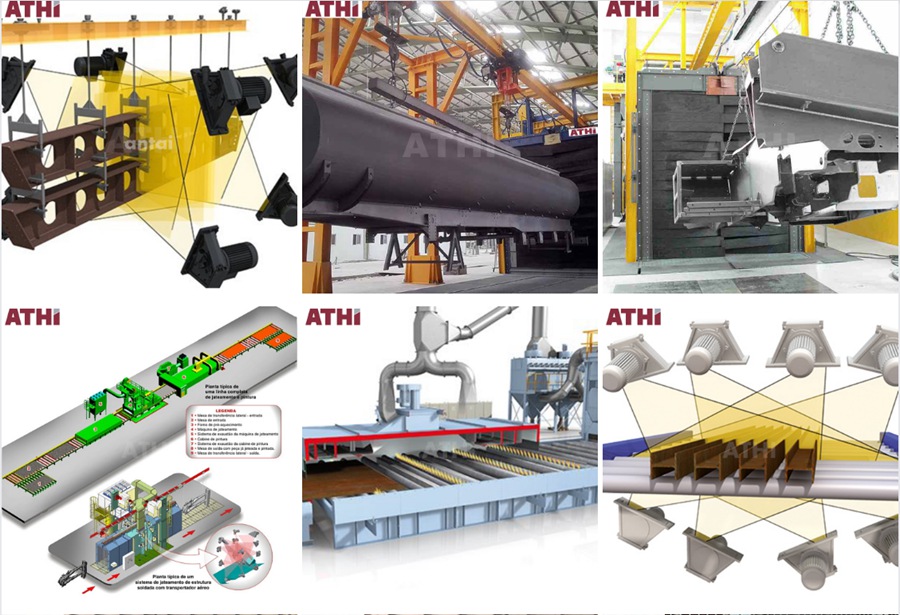

This type of steel plate auto blasting and coating machine is designed and produced by adopting the advantages of similar products from both within the country and abroad. The rusting cleaning part (shot blast cleaning) adopts high-efficient blast wheel and full shutter type shot sand separator. The sweeping machine adopts specially made high-strength nylon rolling brush and high-pressure ventilator. The preheating and drying part may adopt various heating methods. The paint spraying part adopts high-pressure airless spraying method. The complete set of equipment is controlled by PLC, and is the large-size complete equipment of international advanced.

This shot blasting machine and painting line is mainly used for surface treatment (namely preheating, rust removal, paint spraying and drying) of steel plate and various structural sections, as well as for cleaning and strengthening of metal structural parts.

This machine is widely used in Shipyard, ship building industry, machinery industry, etc.

Features

· Complete systems quoted

· One supplier for all components

· Proven abilities - Industry leader

· Quality components

· Proven technology

· Custom designs - Flexible layouts

· Simple integration into existing manufacturing processes

· Wide range of system sizes and variants

Each Paint Room is engineered to the highest quality standards and is supplied with region specific certification. The key elements and processes in a paint room are detailed below:

Overpressure Fresh Air Pumps In order to ensure that dust is not sucked into the room each antai installation is designed to maintain an overpressure situation by pumping fresh air into the room – this also has the effect of controlling the air flow through the room in a down draft or cross draft manner. Box air inlet filters ensure that the quality of the fresh air introduced into the room is dust free.

Lighting Elements Due to the hazardous nature of some paints various categories of lighting element are available from basic units to fully explosion proof.

Filters In order to comply with the environmental legislation concerning the control of overspray paint antai utilize multiple filtration devices including: - Paint Stop Filter: used as a pre-filter to extend the operating life of the main filter - Main Paint Filter: used to extract the overspray paint from the extraction air flow - Active Coal Filter: used to eliminate solvents and smell from the air in the paint room

Electrical Panel The Electrical Panel is the central point from which each of the elements of the paint room can be controlled and monitored. Pre-loaded start up and shut down sequence programs ensure ease of use and the inclusion of the Star-triangle starter guards against electric overload.

What Service Antai can supply?

1. Our engineers can work separately according to the requirements of design for clients of the equipment. and send a customer confirmation to help customers to save costs.

2. During the manufacture of the equipment, we photograph product production progress, and sent to the customer to track the progress.

3. The goods hair go, we will send the original documents for the customer (such as packing list, bill, CO, Form E, Form A, Form F, Form M, B/L etc.)

4. We can provide customers with free English foundation drawing, installation drawings, manuals, maintenance manuals and parts drawings.

5. We can send our engineers to installation and debugging overseas, and free training of operators and maintenance workers.

6. We have a set of After-sales service system, A ID will be sent to each customer, they can log in this system that view all information to buy equipment and parts by it. We provide 24-hour online consultation.

Founded in 2003, Qingdao Antai Heavy Industry Machinery Co.,Ltd. Qingdao formly changed to this name in 2011. Located in the beautiful west coast of Qingdao Jiaonan Coastal Industrial Park, Qingdao ANTAI is a research, design, manufacture, installation and consulting services for the integrated machinery and equipment business.

Company has extensive experience brings together the technical and professional workers, the main products are: shot blasting machine, shot blasting, shot blasting equipment, shot blasting machine, Qingdao, hook type shot blasting machine, sand processing equipment, molding equipment, environmental protection dust removal equipment, and non-standard design and manufacture according to user needs special machinery for specific customers to provide integrated technology solutions.

1.Equipment painting completed before shipment, With Stretch film to avoid rub off the surface paint, It can used wooden cases packaging according to users requirements.(Key parts such as electric cabinet with shockproof packaging material and then packed in wooden cases. )

2. We have 15 experienced engineers, With 108 skilled workers insure good quality of our machines and prompt delivery.

3.Meanwhile our company has a long-term cooperation with ACL, CSCL, CCNI, CNC, COSCO etc insure the goods to the port on time.

According to your infomation, the most suitable machines will be designed for your workpieces.

Tel: +86-532-88138566

Tel: +86-532-88138566 Mobile(Whatsapp): +86-15753219207

Mobile(Whatsapp): +86-15753219207 Wechat: QINGDAO-ANTAI

Wechat: QINGDAO-ANTAI E-mail: Lan.ji@qdantai.com

E-mail: Lan.ji@qdantai.com